Rumored Buzz on China Injection Molding

Wiki Article

Everything about China Injection Molding

Table of ContentsThe Basic Principles Of China Injection Molding China Injection Molding for BeginnersThe Best Guide To China Injection MoldingChina Injection Molding Can Be Fun For AnyoneSome Ideas on China Injection Molding You Should KnowThe Definitive Guide to China Injection Molding

The packaging of material in the shot phase permits added material to flow into the mold and mildew as well as minimize the amount of noticeable contraction. The mold can not be opened up until the required air conditioning time has expired.

When the mold is opened up, a system is made use of to press the part out of the mold and mildew. Force needs to be put on eject the part due to the fact that throughout cooling down the component shrinks as well as abides by the mold. In order to help with the ejection of the component, a mold release representative can be splashed onto the surface areas of the mold cavity prior to shot of the product.

Some Known Details About China Injection Molding

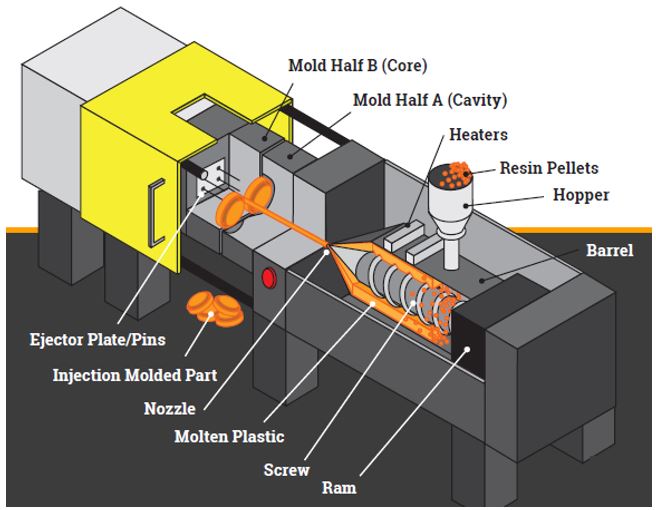

Shot unit The shot system is responsible for both heating as well as injecting the material right into the mold. The initial component of this device is the receptacle, a huge container right into which the raw plastic is put. The hopper has an open bottom, which enables the material to feed into the barrel.

The Only Guide for China Injection Molding

A ram injector compels the material onward via a heated area with a ram or bettor that is usually hydraulically powered. A reciprocating screw moves the material forward by both rotating and gliding axially, being powered by either a hydraulic or electric motor.While it is progressed, the product is thawed by stress, rubbing, and added heating systems that surround the reciprocating screw. The molten plastic is then injected extremely swiftly into the mold and mildew with the nozzle at the end of the barrel by the accumulation of pressure and the forward activity of the screw - China injection molding.

When the product has actually solidified inside the mold and mildew, the screw can retract and fill with even more product for the resource following shot. Clamping system Before the shot of the molten plastic into the mold, both halves of the mold and mildew have to first be securely closed by the clamping system. When the mold and mildew is connected to the shot molding machine, each fifty percent is repaired to a big plate, called a platen.

Excitement About China Injection Molding

The back half of the mold, called the mold and mildew core, is installed to a movable platen, which moves along the connection bars. The hydraulically powered clamping electric motor actuates clamping bars that push the moveable platen in the direction of the stationary platen as well as exert enough force to maintain the mold securely closed while the product is infused as well as subsequently cools down.An ejection system, which is connected to the back half of the mold and mildew, is actuated by the ejector bar and also presses the strengthened component out of the open dental caries. Machine specifications Injection molding devices are usually defined by the tonnage of the clamp pressure they give. The needed clamp pressure is figured out by the predicted area of the parts in the mold and mildew and the pressure with which the material is infused.

Also, particular materials that call for high injection stress might need higher tonnage equipments. The size of the part should likewise abide with various other device specs, such as shot capability, clamp stroke, minimal mold thickness, and platen this content dimension. Shot built components can differ substantially in dimension as well as consequently need these procedures to cover a large array.

China Injection Molding Things To Know Before You Get This

3 Tooling The shot molding process uses mold and mildews, usually made of steel or light weight aluminum, as the customized tooling. The mold has several parts, but can be divided right into 2 fifty percents. Each half is attached inside the injection molding equipment as well as the back fifty percent is permitted to slide so that the mold and mildew can be opened and closed along the mold's parting line.When the mold is closed, the area between the mold core as well as the mold tooth cavity creates the component tooth cavity, that will be full of molten plastic to produce the preferred part. Multiple-cavity molds are occasionally used, in which the 2 mold fifty percents create numerous similar component cavities. Mold and mildew base The mold and mildew core and also mold dental caries are each installed to the mold and mildew base, which is after that taken care of to the platens inside the injection molding equipment.

The rear half of the mold base includes the ejection system, to which the mold and mildew core is connected, as well as an assistance plate. When the securing system divides the mold halves, the ejector bar actuates the ejection system. The ejector bar presses the ejector plate ahead inside the ejector box, which consequently presses the ejector pins right into the molded component.

China Injection Molding Can Be Fun For Everyone

Mold and mildew channels In order for the molten plastic to move into the mold and mildew cavities, several channels are integrated right into the mold and mildew design. my blog First, the liquified plastic enters the mold through the sprue. Additional channels, called joggers, carry the molten plastic from the sprue to every one of the cavities that have to be filled. China injection molding.Report this wiki page